Performance based trust

Welding new material to existing

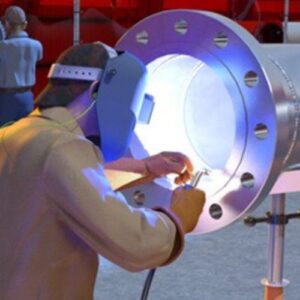

Restricted access to the work

Restricted visual of the work

Environmental influences which impact the weld

Metallurgy resistance to the bond

Weld rejection rate < 2% Field) (< 0.5% Shop)

800+ approved section IX weld procedures

Certified Welding Inspectors